Rotary paddle level switches have been utilized for level detection for any kind of powder material inside a silo, bunker or machine working for its production.

The Motorized (Paddle) Level Sensor is a device designed to mechanically measure material levels in silos and tanks. This sensor operates using a motorized system to monitor material levels. Ideal for solid materials such as powders, granules, and pellets, this sensor stands out for its robust construction and reliable performance. Its easy installation and long-lasting design make it an effective level control solution for industrial applications.

The Vibrating Fork Type Silo Level Sensor is a cost-effective and high-performance product designed to accurately and reliably monitor material levels in silos and tanks. This sensor operates on the vibration principle, sensitively detecting material contact and instantly reporting the fill level.

Conventional motorized and capacitive tank level sensors are not very efficient with low-flow and sticky powder products. As an ideal solution to these challenges, our fork-type silo level sensors are compatible with various materials such as dust, granules, and liquids, delivering high performance in industrial applications.

With its easy installation and maintenance benefits, it enhances operational efficiency and provides a reliable level control solution for businesses.

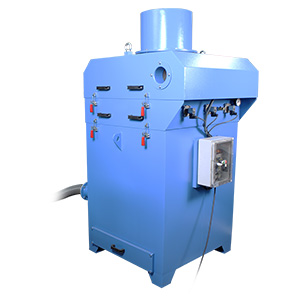

AIRATOR is a product of PULS Elektronik useful in dust material applications that has low fluidity to provide material to flow effectively

An effective filter system that removes dust and particles from the air flow.