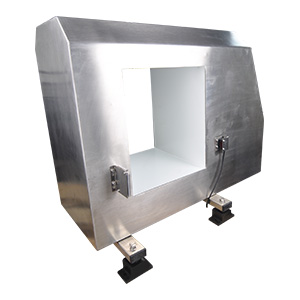

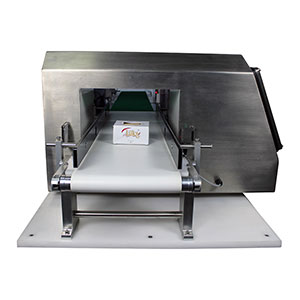

With its technology offering superior detection performance and its high-resistance stainless steel body, it inspects magnetic and non-magnetic contaminant metals with high sensitivity. Our metal detection systems use the transmitter / receiver method based on electromagnetic induction.