Why is Check Weigher (CW) Necessary?

WHY IS CHECKWEIGHER NECESSARY?

Packaging and Processing Companies often utilize CheckWeigher as the "POLICE" on their packaging lines. CheckWeigher serves as the weight control center on the production line, ensuring that unexpected underweight or overweight packages never reach the customer. The National Institute of Standards and Technologies of the Ministry of Commerce defines specific net content rules on packages for wholesalers, retailers, and manufacturers. In addition, the sampling and testing procedure is detailed, specifying how, where, and with what to test. This section determines the minimum number of packages that must be checked, specifies the number of packages that must be opened to understand the package size, and additionally indicates the weight value. This section establishes the number of underweight products that can be allowed, as well as the package weight value within the allowed tolerance for underweight, not exceeding the Maximum Allowable Variation (MAVD).

Packaged products are typically weighed with a CheckWeigher according to the MAVD value depending on the package weight. It regulates and enforces net content laws defined by the State Office of Weights and Measures. The official action to be taken at the end of the package inspection may be verbal advice, instruction, warning, or legal action. Verbal communication between the controller and the organization's authorized person may indicate general compliance with laws and regulations. This discussion may also highlight any inconsistency, sensitivity, or variation in weighing samples worse than the values the controller has obtained on similar packages.

If the control procedure reveals any of the nonconformities listed in this section, the organization has violated legal requirements and the controller may require punitive action. These necessity situations include:

* Excessive grammage deficiency in one or more packages.

* An average negative error condition for all parcel packages.

* Obvious error in the sales transaction on one or more packages with Weight-Price labels.

LEGAL APPLICATIONS AGAINST NON-CONFORMING ORGANIZATIONS

Legal procedures can be implemented in many ways, including through careful judgment, each instruction from the inspector, or the decision of the judge.

* Canceling Sales or Stop orders normally halt all trading until official permission to sell again is given.

* Re-weighing or paying attention to instructions means that a whole batch cannot be sold until the contents or label values are verified (Applicable Only to Random Packs other than Standard Packs).

* The Prosecutor in the case proves the violation of the rules by purchasing or seizing evidence.

* Applications of smart CheckWeigher and weight control techniques allow packaging manufacturers to actually eliminate any customer complaints or legal problems that may arise regarding underweight packages. A well-designed and installed CheckWeigher system significantly helps manufacturers reduce the average filling weight value to the required level with improved CheckWeigher accuracy or feedback to the filling process, preventing the cost increase resulting from heavier (than required) packages.

Where Should You Use CheckWeigher

Manufacturers often use CheckWeigher at the end of the production line before or after the product is packaged. Manufacturers use CheckWeigher to check the fill after filling or to see if anything was forgotten or added after a packer or cartoner.

What Items Does CheckWeigher Typically Weigh?

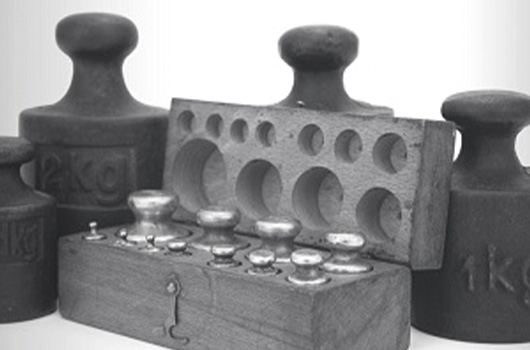

CheckWeigher can and should be used on every manufactured product you can think of, from 1 gram to products weighing hundreds of kg. The following items show which types of products the CheckWeigher can be used for weighing.

* All kinds of packaged food materials; Products such as chocolate, candy, wafers, spices, flour, rice, sugar, tea, etc.

* CDs, Boxed Discs, and other cardboard products; checking for missing paper instructions or anything else.

* Determining whether there is more or less medicine in a bottle or the number of bolts in a bag according to their weight.

* It should be used to increase the density and volume of mixtures such as bread and yogurt or to operate safely, such as volatile airbag batteries.

* Weighing products of varying weights to invoice for warehouse or delivery services or to archive information for future use.

* In the cosmetic and cleaning products sector such as wet wipes and aerosols.