Termocouple,s

Thermocouples

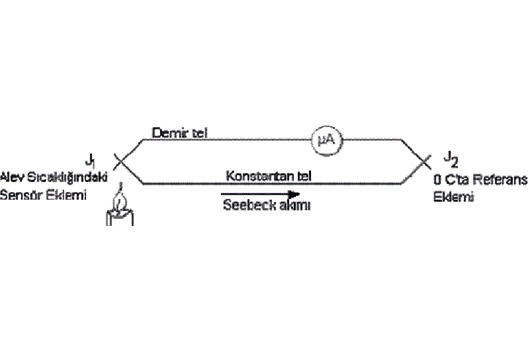

Thermocouples, also known as thermocouples, are created by welding one end of metals with different alloys. If we heat the thermocouples from the welding point, they produce a mV from their free ends corresponding to the feature of the metal pair. This value gives us the temperature information according to the type of element, mV for each type of element. There are tables, according to which temperature information is converted to industrial form. Thermocouples cannot be used in processes in their current state. They need carrier sheaths to protect them from external factors. These sheaths vary depending on the process in which they will work. Thermocouples can reach higher temperatures than thermoresistances.

Between -200 degrees and 1800 degrees, the alloy and wire diameter of the thermocouple are important here and should be selected accordingly. Since thermocouples consist of two different alloys, their connections to the device are made with compensation wires that have the same feature. Although their linearity is lower in certain regions compared to thermoresistances, their great advantages are that they can make faster measurements and that they are resistant to process conditions.

WORKING AREA OF THERMOCOUPLES

- Fe-Const (j type) -200- 800 degrees

- NiCr-Ni (K type) -200- 1200 degrees

- Kromel-Alumel (K type) -200- 1200 degrees

- Pt%10Rh-Pt (S type) 0- 1600 degrees

- Pt%13Rh-Pt (Rtype) 0-1700 degrees

- Pt%30Rh-Pt%6Rh (B type) 0-1800 degrees

- Cu-Const (T type) -200 -300 degrees

- Pt 100 -200 -850 degrees